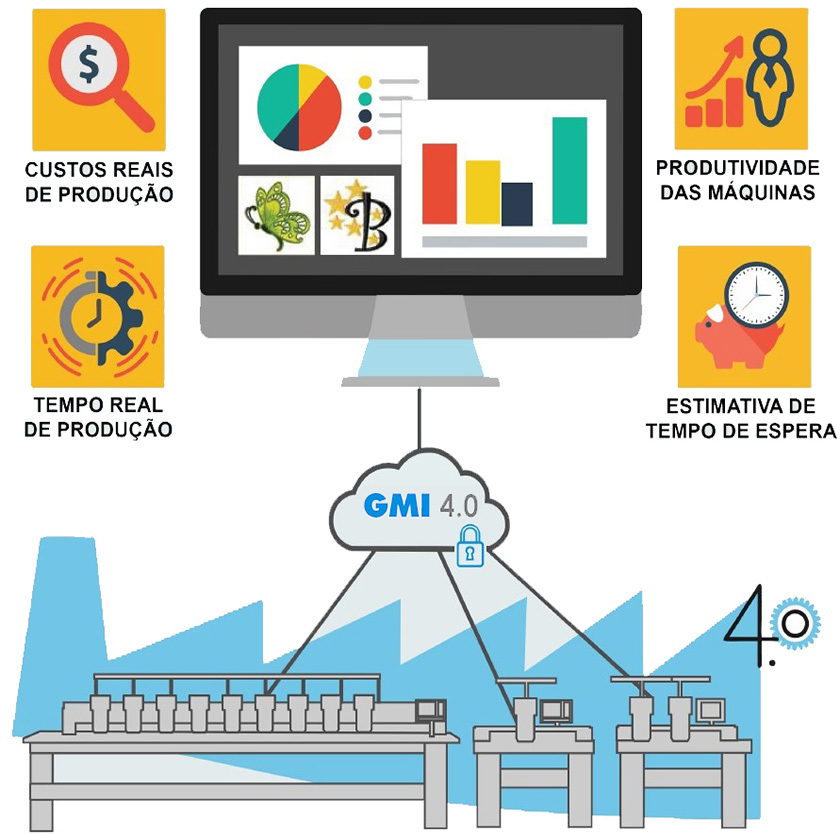

Production Control System – GMI 4.0

Description

The Production Control System, GMI 4.0 is a set of GMI products that promotes the interconnection and automation of all textile production equipment. It is a complete range of hardware and software solutions that aim to increase the productivity of embroidery machines and transform them into Industry 4.0 systems, which are more competitive, automated and digital.

Main features

STILISTA 3 LINK

Embroidery design transfer software through company network.

The software reads, writes and displays embroidery machine files (dst, dsz, dsb, tbf, zsk_tc, fdr_hd, ela, exp and more), generated by Stilista or a third-party software, and GMI files (emg, emg2), prints worksheets and sends the designs to the embroidery machines.

GMI LINK

Embroidery design transfer device through company network.

The system allows to send, via network, the embroidery design to the machines of any brand, with USB or serial port. Alternatively, transmission can take place by reading a barcode generated by the GMI software and printed on the worksheet. Automation makes the production process leaner and leads to the elimination of keys and diskettes.

GMI CLOUD DATA

Production process automation – Industry 4.0

With the GMI Link device, a stitch count sensor and a barcode reader, which scans the barcode printed on the worksheet generated by the Stilista 3 Link software, the customer can monitor the real time order status in a cloud platform (web page with password).

GMI LOGISTICS

Production logistics.

The data control and in cloud system, traces every single order, from order entry to delivery.

Every single production phase, both automatic and manual, the entry and exit of goods can be tracked and controlled, the quality control phase can be checked, goods packaging and deliveries are registered and monitored.

The system is highly flexible and customizable.

GMI MANAGER

Production monitoring & analysis.

Web solution with exclusive access, where the embroiderer/production manager can see, in real time, and from any device connected to the internet, the state of the production process of the embroidery machines, analyze productivity statistics, order status and production history. In addition, taking into account the data entered by the operator and the machine yields registered by the production control, the software calculates the estimates for each work or embroidery order. When analyzing all this data, the embroiderer can schedule production more easily, for example, deciding which machine will make each order. All of this translates into greater efficiency and greater profits.

Production Control System – GMI 4.0